Company Profile

Sanhao Company Introduction

About Sanhao Rubber: Leading Rubber and Silicone Products Factory

Sanhao Rubber was

established in 1984, initially focusing on the production of rubber industrial

components and later expanding into the research and development, as well as

manufacturing of silicone, plastics, elastomers, and various composite

materials. Our departments include domestic and international sales, precision

mold making, material blending, manufacturing, packaging, procurement, quality

control, after-sales service, and administration department. Offering a one-stop

customized service from discussions with customers, development and design,

mold manufacturing, mass production to after-sales service, Sanhao Rubber has

become the preferred supplier for various industries.

Manufacturing Capability

Located in Taichung City, Taiwan, Sanhao Rubber boasts two self-built factories equipped with advanced facilities. Upholding our commitment to product excellence, we continuously improve mold design and mechanical equipment. Currently, our factories house approximately 40 molding machines, including vacuum hot press machines, rubber injection molding machines, rubber cold runner injection molding machines, solid silicone injection molding machines, plastic injection molding machines, TPE calendering machines, and PU casting machines. Additionally, Sanhao Rubber has a comprehensive inspection equipment to meet various product inspection requirements such as dimensions, tensile strength, hardness, etc. We have also developed AI visual inspection systems to enhance inspection capabilities.

Our Service

Continuing the heritage of traditional industries, Sanhao Rubber embraces unrestricted innovation in smart manufacturing, serving industries including agriculture, industry, hydraulics and pneumatics, air and oil hydraulic equipment, automation machinery, technology, automotive, motorcycles, bicycles, transportation, electric vehicles, sports equipment, drinking water and food, and household goods. Our wide-ranging expertise allows us to integrate experiences and help customers find the best solutions, making Sanhao Rubber irreplaceable. Besides professional development, we also bear social and environmental responsibilities, minimizing production pollution, and sincerely caring for our employees and customers, aiming for sustainable business operations.

Our Service

Our offerings include development and design, manufacturing, incoming and outgoing inspections, surface treatment of iron parts, mixing raw materials, combining unrelated materials, drawing, manufacturing, packaging, and shipping.

The production of moulds, including hot pressing, injection, and ejection, is all within our production technology, which allows us to make a lot of adjustments and details, making our production stability very high.

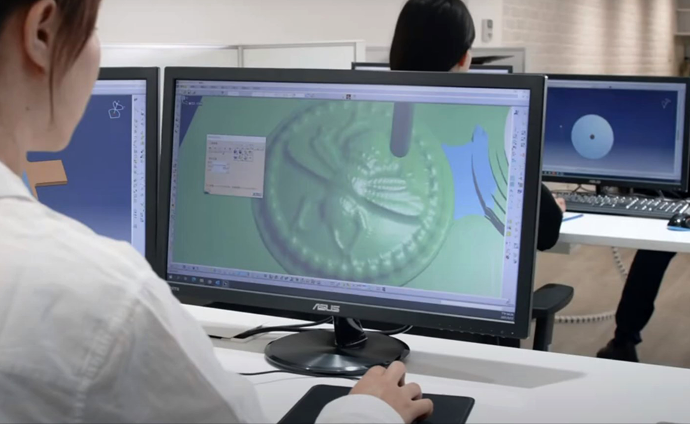

Mould Department: Covering 3D and 2D mould development and drawing capabilities, and with two CNCs (accuracy of plus or minus 1) and a precision discharge machine, the production of moulds, including these three processes, is within our production technology.

On-site Moulding Division: We have hot presses, UR robots, cold runner injection machines, and 6-axis robots on-site, all of which enable us to produce a large number of products while maintaining a steady and effective production mode.

The company serves a wide range of clients, and the majority of the industry categories are in the assembly parts of linear rails, which are followed by sporting goods, which include electric bicycles and bicycle assembly parts; products for sports rehabilitation, like yoga tension belts and rubber strips for weight training; and household items, like silicone soap boxes and rubber suction cups; agricultural machinery, like rubber handles and shock absorbers; and other items. the requirement for fixed stock.

Future Vision

Sanhao is currently creating the business groups of carbon fiber industry: We are currently developing thermoplastic carbon fiber using our formula to enable the processing of recycled carbon fiber into finished goods while maintaining the physical characteristics, strength, and level of the original carbon fiber. We actually achieve environmental friendly and open the door to company sustainability.

Why Sanhao Rubber is the best choice?

Sanhao aspires for each product to fulfil the needs of the customer

while also offering the best use-side solution. For instance, as a rubber

factory with over 30 years of experience, when choosing raw materials for

customers, our selections are frequently more accurate than those made by customers.

Sanhao doesn't need to rely on outside suppliers for the manufacture of moulds

because our company can talk to engineers right away and discuss mould designs,

and scheduling is also free in comparison to outside suppliers. This

significantly lowers the time and financial costs associated with producing moulds

and can hasten the process of creating products for customers. Customers of

Sanhao do not need to consider other external factors besides the product;

Sanhao covers R&D, production, finishing, packaging, and shipping; each

link is done in the factory; the management of each link can be discussed and

coordinated immediately; each link can be strictly controlled by Sanhao.

Sanhao Rubber Company History

2024

Second new factory building.

Installed TPE calendering.

Installed Polytec PU casting machine from Austria.

2022

Installed Arburg Plastic injection machine from Germany.

2019

Established of CNC Mold Department.

2015

Introduced robotic arms systems.

Participated in the Frankfurt Ambiete exhibition.

2014

Participated in the Munich ISPO exhibition.

Obtained ISO14001 certification.

2008

Obtained ISO9001 certification.

2004

First new factory building.

1999

Introduced ERP system.

1984

Sanhao Rubber was founded.