Capabilities

Rubber Mixing Technology

Sanhao Rubber can meet your requirements regarding the physical properties of raw materials; as we know well, added value is derived from high-quality rubber. Therefore, we are devoted to providing our clients with the best composites that conform to their required specifications, in order to guarantee product integrity and customer satisfaction. Our OEM/ODM products have a wide application range and can be applied to any industry.

Through Sanhao's skillful rubber mixing technology, we can produce rubbers with low temperature resistance, oil resistance and abrasion resistance; silica gel which can resist high temperature and conform to FDA; and even composite materials with other designated properties. If you have any questions, please contact us and we will be happy to provide you with more detailed information concerning our services.

Rubber Mold Manufacturing & Design

Sanhao Rubber has been providing excellent rubber mold design, process and finished products to clients for a long time. We can develop molds appropriate for mass production according to the rubber materials used by the clients’ products. The rubber materials range from natural rubber, composite gel and silica gel, to thermo-plastic elastomer.

We concentrate on three kinds of the most common rubber forming molds: press mold, injection mold and casting mold. The precision tolerance of the precision industrial linear guide parts can reach ±0.5mm. The products have good durability and weather resistance and can be applied under high pressure and in extreme climate environments.

We are very proud of having the ability to manufacture such durable materials, and to be able to apply them widely in various industries.

Rubber Product Forming

Our business department is specialized in assisting clients with product customization to shorten the product development time, and use semi-automatic equipment to help clients push the products to the market more rapidly. At Sanhao Rubber, we insist on providing customers with high-quality products, so as to meet the requirements of high specification standards.

We can safely keep the products after their production, and guarantee that the products handed over to the client are intact. Sanhao Rubber offers the following advantages to clients:

- Learn from each other from the products and grow together with the clients.

- The process is recorded in detail, from mold opening, sample making and checking, to mass production.

Sanhao Rubber endeavors to provide product-related assistance to clients. You can rest assured about having your products manufactured by us. To understand more about our rubber products development and manufacturing process, please contact us and we will be more than happy to serve you.

Rubber Products Research & Design

Since our establishment, Sanhao Rubber is constantly pursuing the production of high-quality rubber parts. Our advanced research and design have turned us into a supplier with excellent quality.

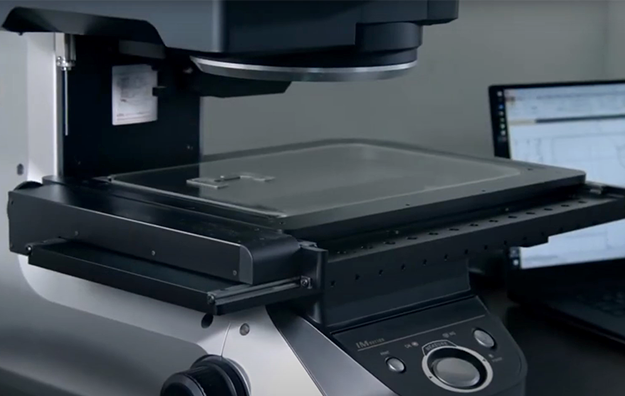

As a top rubber parts manufacturer, we must ensure that our product quality is higher than the industry’s standard and surpasses the expectations of our clients. We guarantee that our rubber products can meet our clients’ specifications all the way from inquiry, materials selection and mold design to production. All the rubber parts produced by Sanhao Rubber must undergo strict testing, including sulfur change, pull, fatigue test, and so on. Our products can meet the requirements of precise performance.

We also offer technical support to answer clients’ questions or help resolve technical problems. Our rich development experience and design skills serve as various supports to our clients. This remains our determination as a high-quality rubber manufacturer.

Customization

Sanhao Rubber's decades of accumulated customization capability are highly respected in the industry. We possess advanced production technology and a professional team capable of developing various rubber, silicone, plastic, and elastomer products according to customer requirements.

From material formulation design, mold design, sample provision to mass production execution, we closely communicate with customers to ensure that products meet their needs and expectations. Sanhao Rubber is able to quickly respond to customer demands, providing high-quality, efficient customized services, making us a trusted partner for our customers.

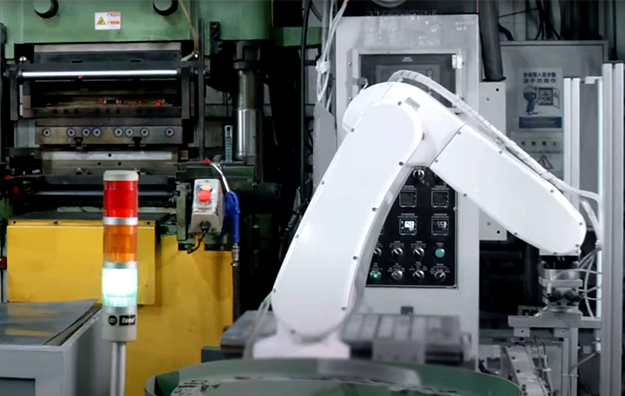

Smart Manufacturing

Sanhao Rubber is committed to smart manufacturing, utilizing advanced production equipment and technology to achieve automation and intelligence in the production process. The company is equipped with world-class robotic arms, German Arburg injection molding machines, AI optical inspection, and other advanced equipment, combined with digital management systems to enhance production efficiency and product quality, while reducing costs and shortening delivery cycles, providing customers with better services.

Manufacturing capacity

Sanhao Rubber boasts robust manufacturing capabilities, with advanced rubber production and mold-making technologies. The company focuses on rubber parts manufacturing and plastic parts development and production, catering to various industry applications. With dozens of rubber and silicone molding machines, rubber and silicone injection molding machines, PU casting machines, plastic injection molding machines, and complete inspection equipment in-house, Sanhao Rubber ensures rapid and efficient completion of sample prototyping, batch testing, and mass production execution, guaranteeing the timely delivery of high-quality products.

Quality policy

Sanhao Rubber always prioritizes quality and adheres to strict quality management policies. The company holds ISO 9001:2015 and ISO 14001:2015 quality management system certifications, implementing rigorous control measures at every stage from incoming inspection to production processing and final factory testing to ensure products meet customer quality requirements. Sanhao Rubber is dedicated to continuously improving its quality management system, enhancing product quality and customer satisfaction, and becoming a trusted partner for customers.